Improve steam boiler processes and save costs

Reduce steam, water and energy, simplify service and maintenance

With qualitative monitoring and control of feed water boilers and steam boilers

Companies should always produce their products flexibly and on time. The production processes are optimized accordingly to meet these challenges. In order to ensure an overall economical and flexible driving style of the entire production chain, upstream processes also have to be adapted.

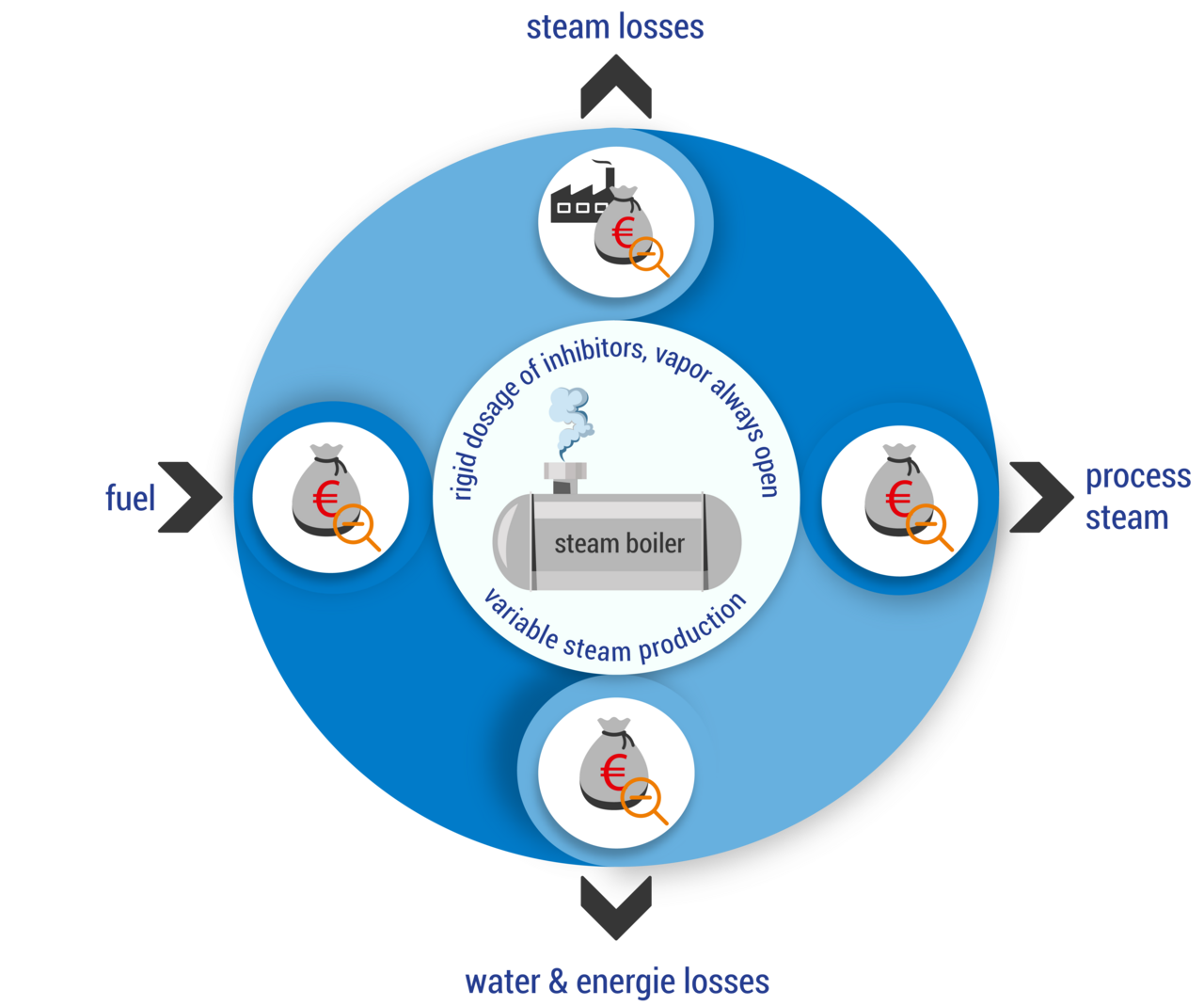

The flexible production of sufficient quantities of steam for the manufacture of products is absolutely necessary. But in practice the operation of the steam boiler is mostly rigidly set. The dosing amounts of inhibitors are fixed set to the maximum amount of steam required to ensure safe steam production. With reduced steam production, there are rather unnecessary losses of energy and water. Because when less steam is produced, the vapors remain open and the dosage is not reduced.

Rigid dosing of inhibitors in the steam boiler costs time, money, water and energy

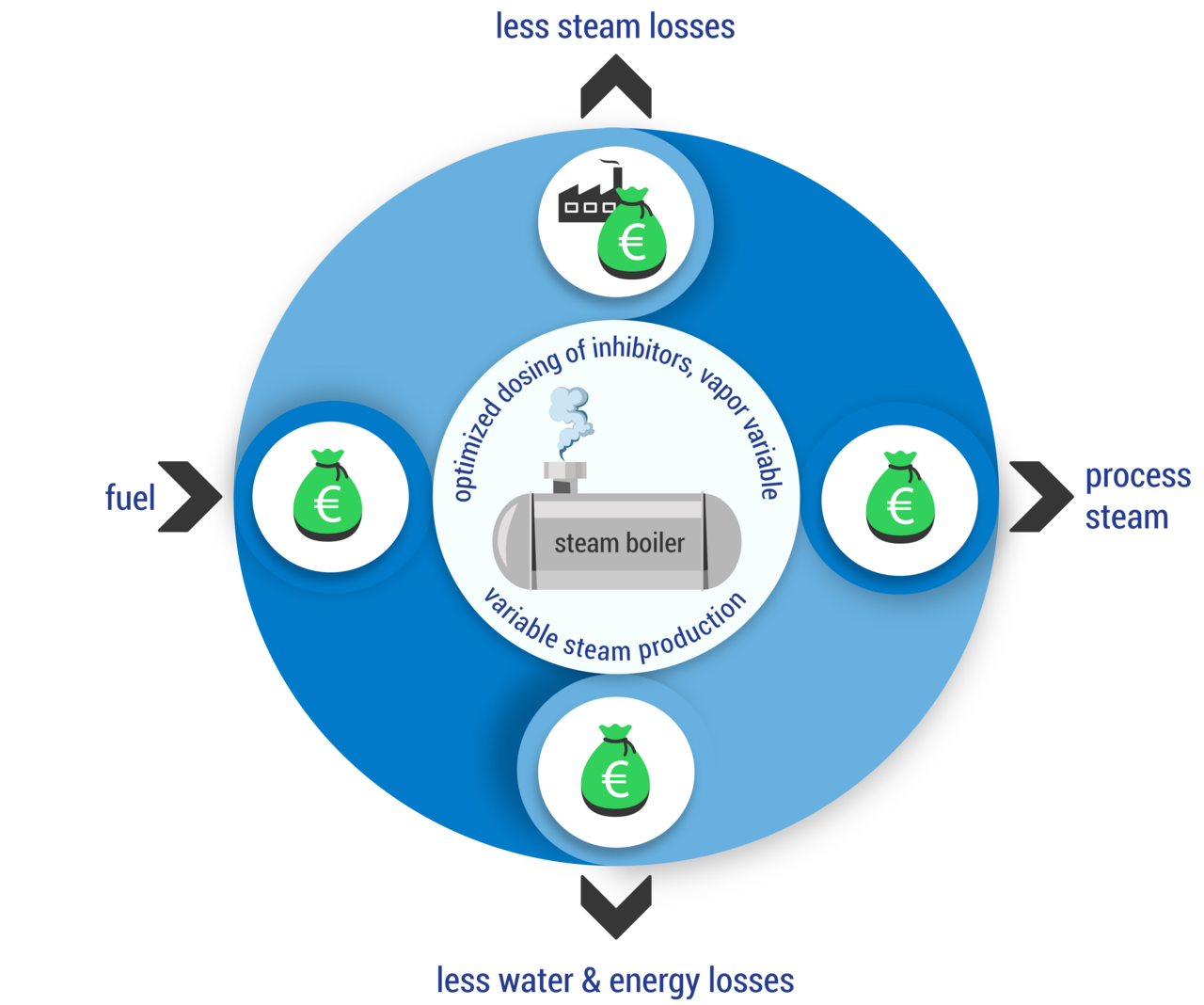

Optimized dosing of inhibitors leads to savings in water, energy and service

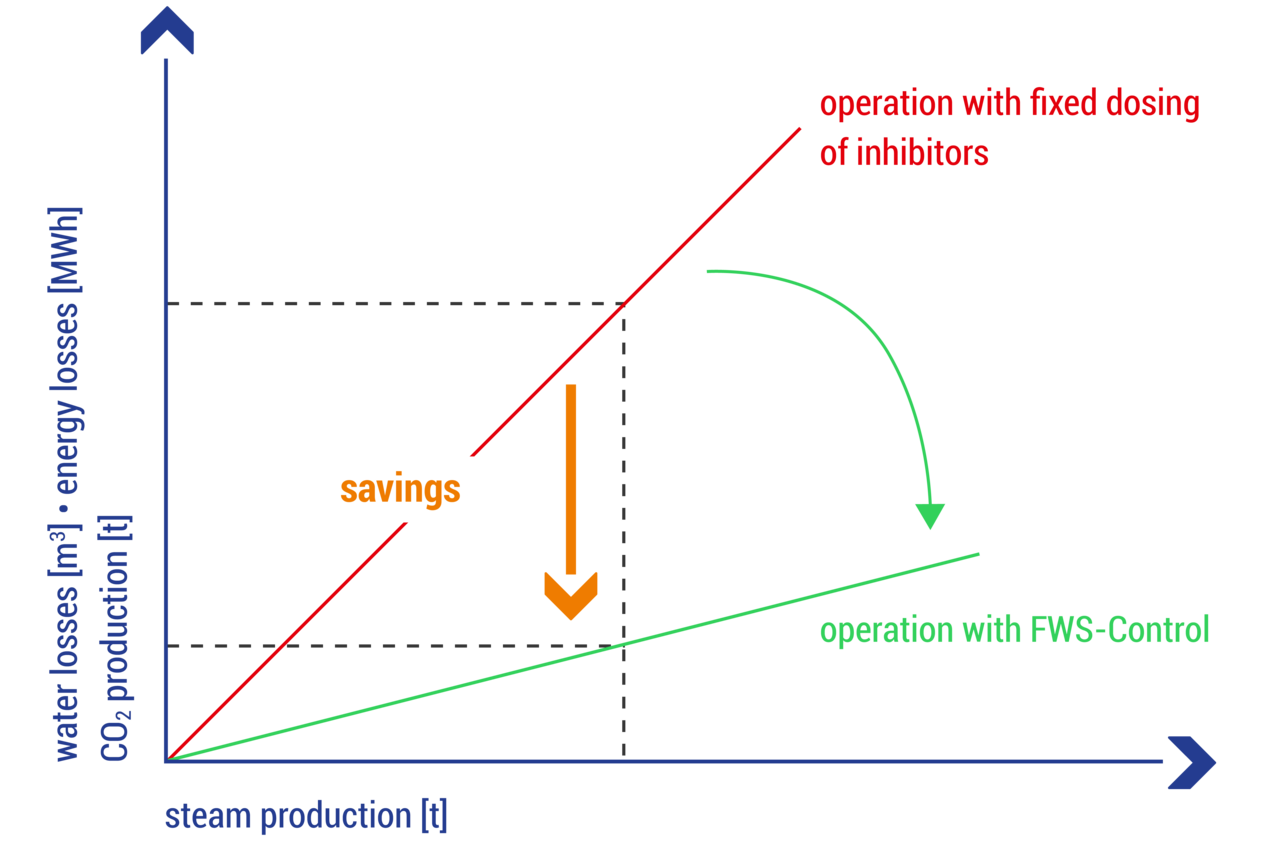

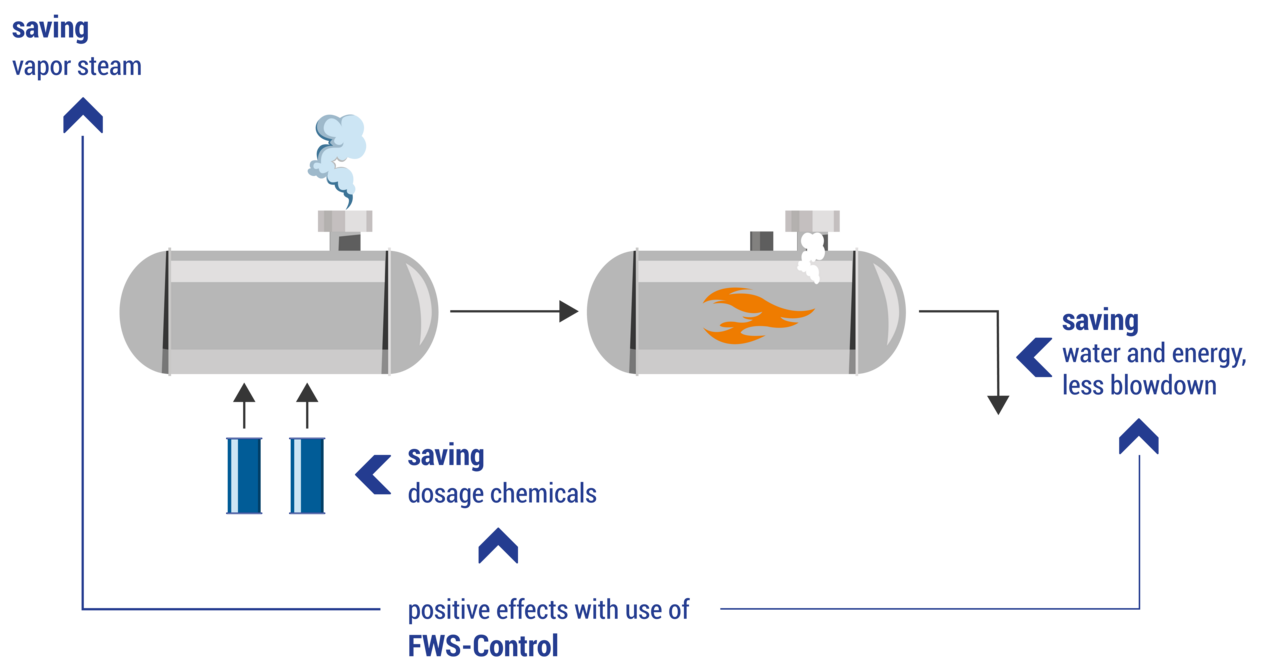

With qualitative monitoring and control of the steam boiler, the costs of water, energy and carbon dioxide are reduced. And that with consistently flexible and secure production processes.

Intelligent monitoring of the steam boiler with an optimized control system improves the efficiency of the boiler system with less costs and losses.

Save steam vapor

Losses previously ignored can contribute to detectable savings in boiler operation.

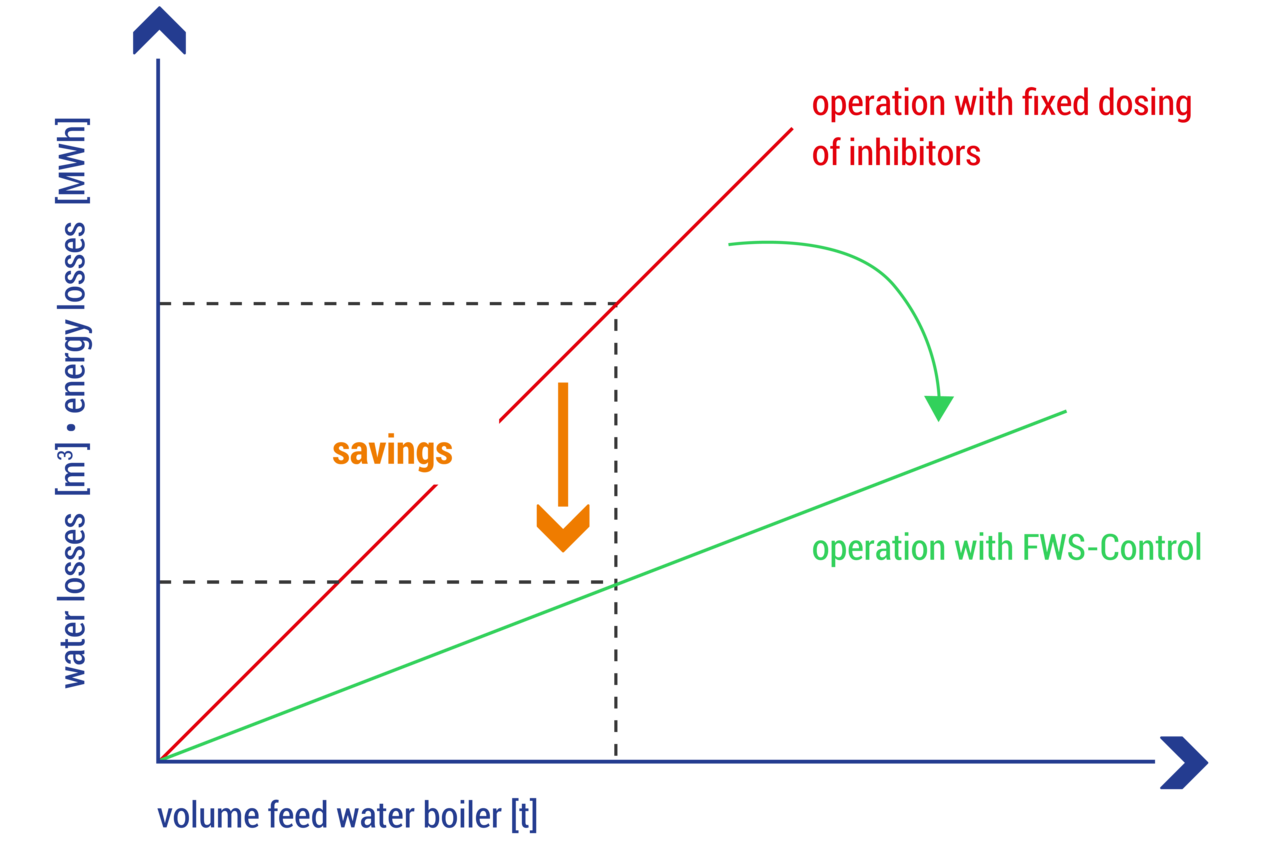

In practice, the vapor valve of feed water boilers must be kept open to guarantee thermal degassing. However, oxygen-free water enables a vapor valve to be closed if these requirements are met. So steam losses are reduced to the most necessary. With a qualitative monitoring of the dissolved oxygen content in the feed water and an automatic control of the vapor valve, unnecessary water and energy losses are prevented. Furthermore, in connection with the dosing control for the oxygen binder, an unnecessary salting-up of the feed water (up to 10 mg / l sodium sulfide) is prevented. There is also an improvement in the thickening in the steam boiler and a reduction in blowdown. This saves fuel, treated process water and carbon dioxide and the entire process is more efficient.

Saving water, energy and carbon dioxide through online measurement of feed water with vapor control

Volume of feed water boiler

Overpressure in the feed water boiler

Condensate content to the feed water

Effect per year

Water saving

Energy saving

CO2 saving with fuel heating oil

CO2 saving with fuel natural gas

Quality-controlled dosing of inhibitors by constantly monitoring the water in the feed and steam boiler

The rigid dosage setting for agents for oxygen binding and alkalization for maximum production of steam have negative consequences. Because with reduced production of steam, much less chemicals are required.

A pH value of 9 to 10 in the feed water is quite possible and legally permissible. However, the consumption of chemicals increases up to 10 times. This results in an up to 10 times increase in energy and water losses.

Permanent monitoring and control of pH, residual oxygen and conductance enables a reduced dosage of inhibitors to a necessary minimum. The result is less loss of energy and water in the steam boiler. At the same time, the efficiency of steam boiler operation improves and carbon dioxide emissions are also reduced.

Saving water, energy and carbon dioxide by online measurement with quality control of inhibitors

Pressure rating of steam boiler

Blowdown conductivity of steam boiler

Ø conductance of make-up water

Ø pH value feed water

Steam production per year

Effect per year

Water saving

Energy saving

CO2 saving with fuel heating oil

CO2 saving with fuel natural gas

Total water, energy and carbon dioxide savings by online measurement with quality control of inhibitors and vapor valve

Total effect per year

Water saving

Energy saving

CO2 saving with fuel heating oil

CO2 saving with fuel natural gas

Total water and energy savings based on the total annual amount of steam production

Total effect per year (per ton of steam)

Water saving

Energy saving

The results from the tables will differ in practice, since not all concrete conditions can be taken into account in this form. These results should be your first decision-making aid for optimizing and increasing the efficiency of your steam boiler system.

Control and dosing of feed water and steam boiler

HWA Analyzer

HWA Analyzer offers comprehensive control and control of important parameters of the entire feed water and steam boiler system. The user-friendly handling leads to more efficiency, safe operation of the system and savings in energy and costs.