Problems and costs of steam boiler and reverse osmosis

For many industrial processes it is necessary to remove the hardening agents in the water. However, if technical problems with the water softener remain undetected, the hardness agents can form poorly soluble compounds, which are deposited, for example, in steam boilers in pipes, tanks and claddings. These deposits form the cause of corrosion and heat loss. In reverse osmosis, irreversible membrane losses are predictable.

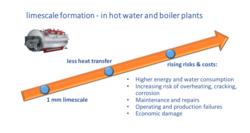

Steam boiler - 1 mm limescale layer leads to approx. 20% loss of effectiveness

If, for example, raw water at 360 ppm flows into a steam boiler for 10 hours, a 1 mm layer of limescale will already form on the inside cladding of a boiler. The result is reduced heat transfer and up to 20% loss of effectiveness. The thicker the layer of limescale, the higher the risk of overheating, cracking and corrosion. At the same time, the consumption of energy and water as well as the services due to increased repairs and maintenance are increasing. In the worst case, it can lead to operational and production downtimes.

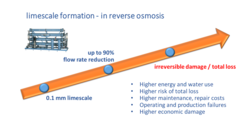

Reverse osmosis - 0.1 mm limescale layer leads to approx. 90% loss of effectiveness

In reverse osmosis, the consequences of hard water breakthroughs are much faster and more serious. The membranes block within a short time due to their crystallization.

Even a layer of limescale with a thickness of 0.1 mm can lead to a loss of effectiveness of up to 90%. Irreversible damage and total loss are the worst consequences. Until this happens, even the smallest amounts of hard water lead to higher wastewater and reduced permeate. Maintenance and repairs are increasing, up to irreversible membrane losses and complete production downtimes.

Constant monitoring of the softener can prevent damage

To prevent this, continuous monitoring of the water softener is necessary. Solutions from OFS GmbH are used to examine the soft water at the outlet of the softener twice a minute for increased hardness values. If the specified limit is exceeded, an alarm is triggered.

For example, approx. 50,000 m³ soft water can be checked with up to 500,000 measurements. The particularly low-maintenance and sensitive system with the integrated calcium- and magnesium-selective sensors monitors itself. This ensures a safe operation and process flow.